Despite having features like GPS tracking systems, driverless functioning, and robotics, modern machines still require a human element to maintain and run them, mainly to prevent breakdowns.

Unfortunately, machinery repairs require a lot of time and money, and breakdowns are expensive. Additionally, breakdowns might keep site employees from working for hours or even days, depending on how long it takes to fix the machine issue.

It’s safe to conclude that preventing breakdowns in the first place is the best method to handle them. While this might not always be achievable, there are some easy steps you can take to avoid breakdowns in the first place and learn how to deal with them.

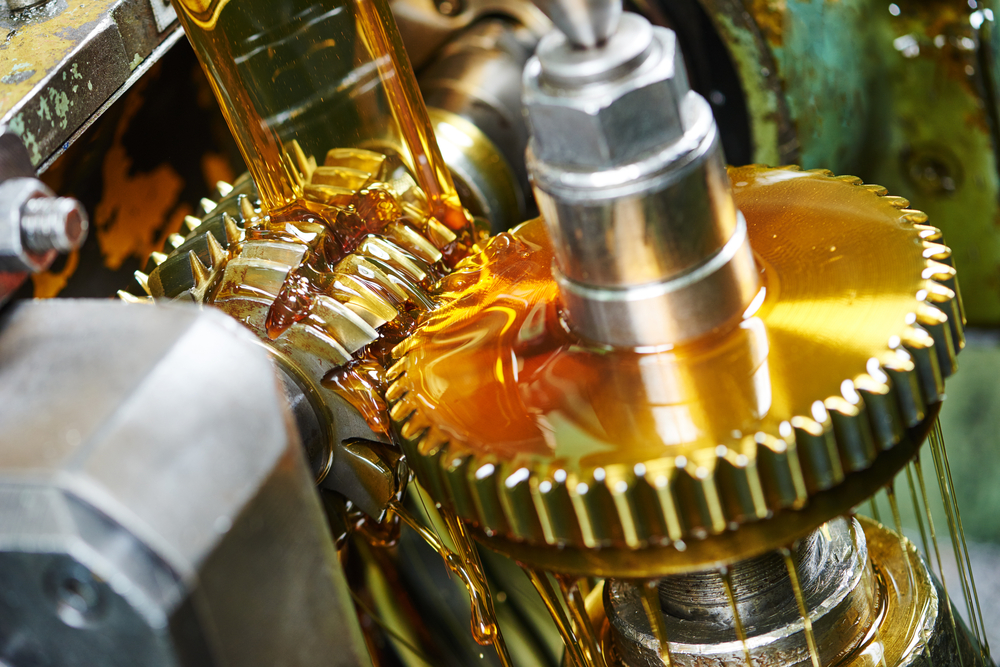

Routine maintenance

Regularly checking your machines and equipment will prevent them from breaking down unexpectedly. During a routine check-up, ensure everything is working perfectly and that parts that need changing are changed then and there. A preventative maintenance routine is costly, but having a breakdown on site will cost you more – both money and time.

Clean and store them appropriately.

To extend their lifespan and improve performance, you must clean and store your equipment appropriately. You should properly store them when not in use to protect them from weather conditions, including rain, morning frost, and severe heat.

Also, cleaning will maintain your machinery’s and other equipment’s peak performance. There is a need for routine cleaning because dirt tends to accumulate over time and could potentially obstruct pipes, vents, and other openings. Although rust is unavoidable, proper cleaning and storage can help your equipment last longer by preventing rust from spreading.

Replace parts when needed

Another critical thing to ensure the efficiency of your plant machinery is replacing parts when needed. Over time your machinery parts are prone to wear and tear due to frequent use. But you don’t have to linger until the worn-out parts completely break down to replace them. Replacing damaged equipment parts with quality ones from a reputable manufacturer such as Kor Pak is advisable.

Avoid overworking your machines.

Never overwork your machines regardless of how efficient they seem because that results in damage in the long run. Machines have a working limit, just like humans do. Overworking a machine will typically result in overheating, indicating that your machinery has reached its limit. Give your equipment a break and some time to cool down if you find that it is becoming hot or that it is not performing well.

Follow the operator’s manual

A machine operator’s manual contains all sorts of instructions on operating and maintaining the machine to ensure long-term service. Manuals also provide warnings and advice about safety. Learn this crucial information because it might come in handy later.

The takeaway

It is wise to be prepared because breakdowns on the job site can happen unexpectedly. A good tip is to have an emergency plan in place for breakdowns. To avoid spending too much time before resuming work after a breakdown, anticipate the types of equipment or machinery malfunctions and list potential solutions.

Why You Should Join a Minecraft Towny Server Today

Why You Should Join a Minecraft Towny Server Today  The Science Supporting Natural Wellness from Green Kratom

The Science Supporting Natural Wellness from Green Kratom  Myths About CBD That Need to Be Debunked

Myths About CBD That Need to Be Debunked  How to protect yourself when using a deep web search engine?

How to protect yourself when using a deep web search engine?  Are CBD Gummies for Anxiety a Miracle Cure?

Are CBD Gummies for Anxiety a Miracle Cure?  Liquid Vaults: Ether.fi unlocks automated DeFi earnings

Liquid Vaults: Ether.fi unlocks automated DeFi earnings  How to share legal advice securely using self-destructing notes?

How to share legal advice securely using self-destructing notes?  Maximize your wins: Top Strategies for Football Betting in Online Casinos

Maximize your wins: Top Strategies for Football Betting in Online Casinos  Five Businesses You Could Start Today for Additional Income

Five Businesses You Could Start Today for Additional Income