Whether you like it or not, when you are sourcing your ACME thread gauges and thread taps one of the biggest challenges that you are bound to face is delays in the sourcing process. Unless you have adequate experience in sourcing thread gauges and thread taps, you may not be able to handle the delays and get your orders sourced in a timely fashion. Here are a few crucial areas that you are required to focus when trying to source your thread gauges and thread taps.

Most often customers run into delays only when they do not select their suppliers with adequate care. There are so many Metric tap and thread gauge suppliers in the industry and you cannot select any random supplier. You will have to closely review the suppliers and identify the most trusted companies based on their experience and based on your requirements. Not every company would be a best fit for your requirements.

In order to establish the supplier that you are considering is the best fit, first you need to understand their capabilities. Will they be able to meet your requirements? In case you have custom requirements, your suppliers must be able to deal with those requirements and deliver effectively.

Secondly, they may have the technical capabilities and the experience but they should be capable of handling your order volume. In case you have a high volume order, unless your manufacturer is fully equipped and well-staffed, they will not be able to deliver your orders on time. Before you place the order with any supplier you need to understand their turnaround times and only then you must take things forward. Only if they are able to promise you a timely delivery you must proceed. In case if they fail to honour their delivery promises, then you must consider switching to a new company.

It is also important to understand that your manufacturer would need enough time to manufacture your custom orders. You should not therefore wait until the last minute to place your order. You must place your orders well in advance so that there are no issues with the timely delivery of the thread taps and thread gauges.

What is even more important is careful planning of your sourcing calendar. You would know your general requirement trends and based on that you should plan your sourcing schedule. Always try to stay ahead of your requirements cycle. You should always have two sets or two cycles of readily available tools in your inventory. Only then if there are any delays you will be able to address them effectively and such delays would not disrupt your production cycle.

Delays in the delivery of the orders happen due to various reasons. It is not always due to the manufacturer. At times the delays could also be due to the customer’s lack of experience in sourcing and in their lack of careful planning with regard to tool sourcing.

Home Protection Reinvented: How Private Security Elevates Safety in Houston and Dallas

Home Protection Reinvented: How Private Security Elevates Safety in Houston and Dallas  Best Eminence Organics Products for Sensitive Skin in Canada

Best Eminence Organics Products for Sensitive Skin in Canada  Which Bitcoin slot bonuses trigger most often?

Which Bitcoin slot bonuses trigger most often?  What are 6 bitcoin casino roulette methods for limitless opportunity creation?

What are 6 bitcoin casino roulette methods for limitless opportunity creation?  How to Choose the Perfect Home with a Garage for Sale in Kansas City

How to Choose the Perfect Home with a Garage for Sale in Kansas City  How can players manage limits while playing casino games?

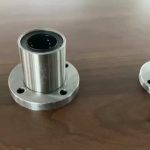

How can players manage limits while playing casino games?  Ball Bearing Slides on Smooth Shaft: The Secret to Precise, Friction-Free Motion

Ball Bearing Slides on Smooth Shaft: The Secret to Precise, Friction-Free Motion  What should beginners know before playing online slots?

What should beginners know before playing online slots?  Essential Strategies to Prevent Tick Encounters Around Your Property

Essential Strategies to Prevent Tick Encounters Around Your Property